dust filtration, coalescers, separators - we can all produce!

No matter which brand - we can produce!

No matter which model - we can produce!

You have needs - please contact us.

|

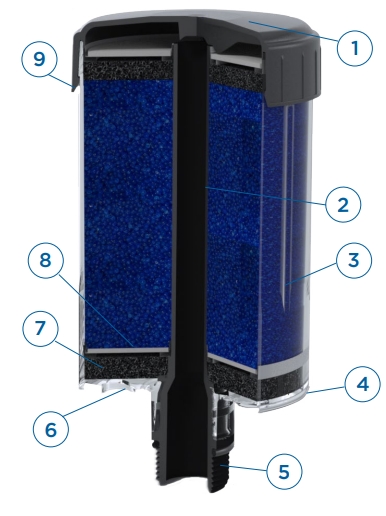

The Air Desiccant Breather line sets the standard for contamination control. These breathers have state-of-the-art features that reduce particulate and moisture contamination, keeping your equipment and fluids lasting longer.

The innovative breather line integrates check valve technology in a desiccant breather and offers replacement cartridges, to significantly reduce maintenance costs. The clear view 360 degree design makes it easy to inspect the saturation of the colour-changing silica gel from a distance. The inert silica gel turns from gold to dark green to visually indicate the adsorption of moisture and confirm the breather is getting the job done.

Complete range of particle breathers in combination with desiccant breathers, silica gel breathers, dehumidifiers and air breather dryers in different sizes and versions. Robust design for the most challenging applications. Shock- and impact-resistant SAN plastic housing with integrated UV protection. Internal stainless steel tube with male BSP connection thread (NPT on request) for maximum stability. Full serviceability: Replaceable 3µm air filter elements as a spin-on cartridge in a metal casing and replaceable desiccant material. Wide range of accessories and options.

The ‘R’ Series (Economy) transformer breathers are manufactured from UV stabilised polycarbonate and are available in 3 sizes. The clear polycarbonate body allows users to easily monitor the condition of the desiccant.

The unit is mounted from a ¾” female pipe thread connection at the top of the breather. This connection point is also used for filling and emptying the desiccant within the breather.

Two-way, low pressure valves are fitted in the base of the breather to ensure that the atmospheric air enters the desiccant when a negative pressure differential occurs within the equipment being protected.

These units can be connected in parallel using the new "Dual Breather" manifold where increased capacity is required. This doubles the time between maintenance and allows the use of the economy series breather on larger transformers which would otherwise require a more expensive breather.

Features

High performance UV stabilised clear polycarbonate

IP65 rating

ISO9001/2008 design approved

Suitable for 1250 kVA to 750 MVA Transformers

Operating temperature range –50°C to +70°C

Weather resistant

Simple installation

Low dusting beaded silica gel desiccant

Indicating desiccant changes from blue – pink; orange - green

Installation

The breather is supplied with a threaded sealing plug screwed into the top moulding to prevent any water vapour ingress whilst in storage. This plug should be removed immediately prior to the unit being fitted to the air vent pipe of the transformer reservoir tank. Fit the breather and tighten using the spanner flats provided at the top of the unit. Maximum torque on threads is 9Nm/80lbfin.

NOTE: DO NOT ATTEMPT TO SCREW OR UNSCREW THE BREATHER BY HOLDING THE BODY WITH YOUR HANDS, USE A SPANNER ON THE FLATS PROVIDED.

Maintenance

When the desiccant becomes saturated, follow the steps below for changing out the spent silica gel. (Alternatively, entire breather can be replaced.)

Unscrew the breather from the vent pipe.

Remove the perforated cover in the top moulding and empty the spent silica gel from the container. This material may be disposed of in a normal landfill.

Fill the container with active orange or blue silica gel and lightly tap the container to settle the desiccant and top up if necessary.

Replace the perforated cover and screw the breather back onto the vent pipe.

Our filtration equipment is used in a wide range of industries:

| Contact us | john Fimler Filter WeChat: +8613632692595 Whatsapp:+8613632692595 E-mail:4798742@qq.com |