dust filtration, coalescers, separators - we can all produce!

No matter which brand - we can produce!

No matter which model - we can produce!

You have needs - please contact us.

|

Warm Tips:

We can supply most of the manufacturers of filter accessories, complete model, the goods quickly, quality assurance.

Limited space, not one by one show, if demand, please contact, thank you!

Air filtration, liquid filtration, gas filtration, hydraulic oil filtration, petroleum filtration,

dust filtration, coalescers, separators - we can all produce!

No matter which brand - we can produce!

No matter which model - we can produce!

You have needs - please contact us.

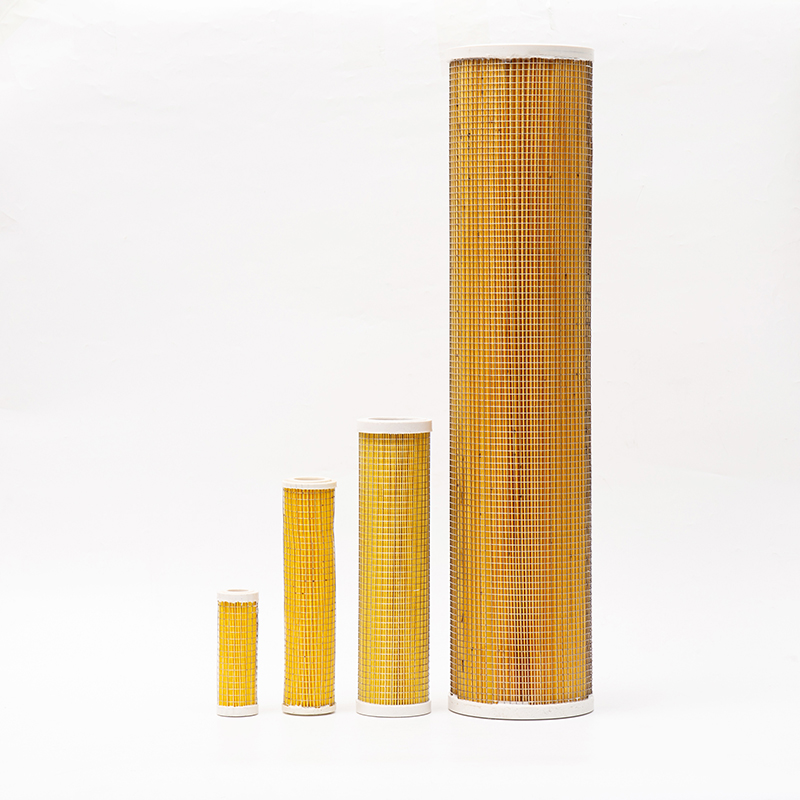

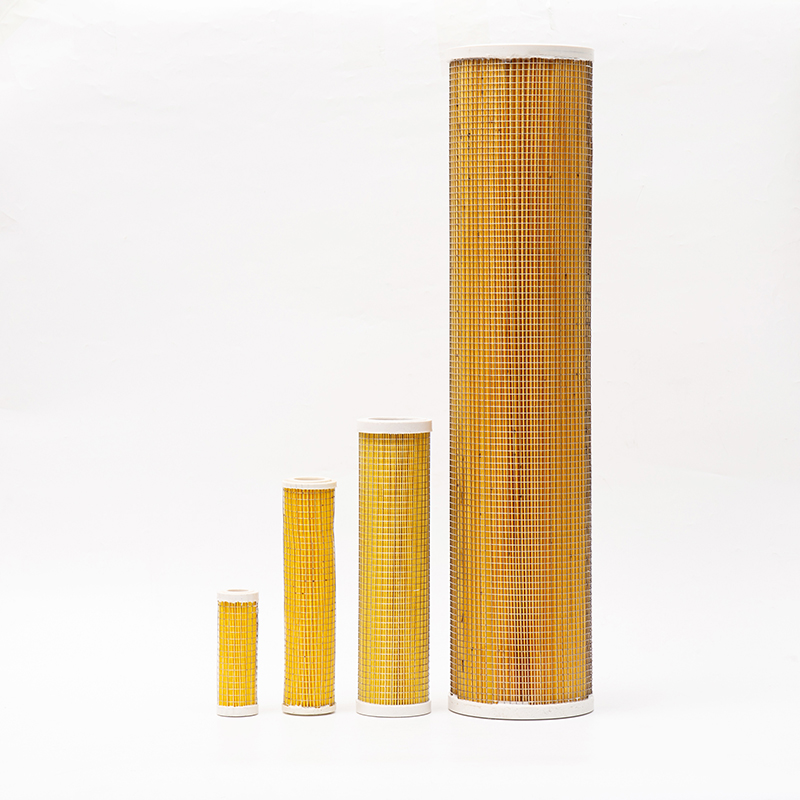

Compressed Air Filter Elements

The compressed air in compressor systems is sent to the air tank to be stored by passing through various filtration stages. The humidity in the air exposed to pressure in the rotor part of the compressor and then in the air tank can turn into water particles at a level that can damage the system. Unfiltered water particles cause corrosion, especially in systems where compressed air is used, resulting in a decrease in system efficiency and an increase in maintenance costs. In-Line filters with special filtration properties and low micron values produced by Filsan Filter are used in order to prevent damages that may occur from such undesirable situations, to increase system efficiency and to minimize maintenance costs that may arise from moisture.

Filter Element Types

AUX replacement filter elements which are the productions of wide research and special design, can be utilized in many areas of industry for different applications. These type of filter elements are installed in compressor dryers as filter units made of one or more filters in succession.

In the first and the second stages of filtration solid and liquid particules of 1 to 5 microns are retended successivelly at very low pressure losses.

The third stage elements are for high pressures and filters the particules of down to 0.01 micron. Another variety of these filter elements is the ones contain active carbon. By this way, it removes odor and oil vapor particles down to 0,003 ppm. These highly efficient elements are designed to be used in applications of medical and food precessing. Upon request of compressed air manufacturers, special designs or enhanced types of filter elements may also be manufactured.

Particulate compressed air filters are used to remove dust and particles from the air. The air stored in the air tank, before being sent to the dryer system, passes through a filter with a filtration capability of up to 3 microns as a pre-filter, and the pollutants that may be in the air are filtered before they reach the coalescing filters.

Coalescing filters are used to capture oil and/or moisture that is suspended in the compressed air in very tiny droplets. The air that comes from the pre/particle filters, free of pollutants that can reduce the life and efficiency of the coalescing filters, is filtered down to 1 micron in the coalescing inlet (Blue) filter and sent to the dryer system. By the special gases in the dryer system, the moisture in the air is condensed by cooling and it is filtered in the Output (Red) coalescing filter, which has a sensitive filtration feature up to 0.01 micron, and is brought to a humidity level that will not harm the system.

Activated carbon filters will remove odors and vapors. Filsan’s Activated carbon filters are; filters used to prevent gas molecules in the air drawn from outside in compressor systems and cause bad odor. Activated carbon filters are important in compressor systems in terms of ensuring that the odor in the dehumidified air or any gas molecule that may be harmful is given to the system in a purified manner after the in-line filters. These filters perform the filtration process as a result of the harmful gas molecules in the air sticking to the active carbon in the structure of the filters.

4C10-025 Coalescer

4C10-050 Coalescer

4C15-060 Coalescer

4C15-095 Coalescer

4CU25-130 Coalescer

4CU25-187 Coalescer

4CU25-235 Coalescer

4CU35-280 Coalescer

6C10-025 Coalescer

6C10-050 Coalescer

6C15-060 Coalescer

4DS35-280 High Temp Coalescer

6DS10-025 High Temp Coalescer

6DS10-050 High Temp Coalescer

6DS15-060 High Temp Coalescer

6DS15-095 High Temp Coalescer

6DS25-130 High Temp Coalescer

6DS25-187 High Temp Coalescer

6DS25-235 High Temp Coalescer

6DS35-280 High Temp Coalescer

8DS10-025 High Temp Coalescer

8DS10-050 High Temp Coalescer

10QU25-235 Coalescer w/ built-in prefilter

10QU35-280 Coalescer w/ built-in prefilter

7CVP25-130 Coalescer

7CVP25-187 Coalescer

7CVP25-235 Coalescer

7CVP35-280 Coalescer

3PU10-025 Particulate

3PU10-050 Particulate

3PU15-060 Particulate

3PU15-090 Particulate

3PU25-130 Particulate

6C15-095 Coalescer

6CU25-130 Coalescer

6CU25-187 Coalescer

6CU25-235 Coalescer

6CU35-280 Coalescer

8C10-025 Coalescer

8C10-050 Coalescer

8C15-060 Coalescer

8C15-095 Coalescer

8CU25-130 Coalescer

8CU25-187 Coalescer

8DS15-060 High Temp Coalescer

8DS15-095 High Temp Coalescer

8DS25-130 High Temp Coalescer

8DS25-187 High Temp Coalescer

8DS25-235 High Temp Coalescer

8DS35-280 High Temp Coalescer

10DS10-025 High Temp Coalescer

10DS10-050 High Temp Coalescer

10DS15-060 High Temp Coalescer

10DS15-095 High Temp Coalescer

10DS25-130 High Temp Coalescer

3PU25-187 Particulate

3PU25-235 Particulate

3PU35-280 Particulate

100WSU10-025 Water Separator

100WSU10-050 Water Separator

100WSU15-060 Water Separator

100WSU15-090 Water Separator

100WS25-130 Water Separator

100WS25-187 Water Separator

100WS25-235 Water Separator

100WS35-280 Water Separator

8CU25-235 Coalescer

8CU35-280 Coalescer

10C10-025 Coalescer

10C10-050 Coalescer

10C15-060 Coalescer

10C15-095 Coalescer

10CU25-130 Coalescer

10CU25-187 Coalescer

10CU25-235 Coalescer

10CU35-280 Coalescer

4IU10-025 Coalescer

10DS25-187 High Temp Coalescer

10DS25-235 High Temp Coalescer

10DS35-280 High Temp Coalescer

4QU10-025 Coalescer w/ built-in prefilter

4QU10-050 Coalescer w/ built-in prefilter

4QU15-060 Coalescer w/ built-in prefilter

4QU15-090 Coalescer w/ built-in prefilter

4QU25-130 Coalescer w/ built-in prefilter

4QU25-187 Coalescer w/ built-in prefilter

4QU25-235 Coalescer w/ built-in prefilter

4QU35-280 Coalescer w/ built-in prefilter

AU10-025 Adsorber

AU10-050 Adsorber

AU15-060 Adsorber

AU15-090 Adsorber

AU25-130 Adsorber

AU25-187 Adsorber

AU25-235 Adsorber

AU35-280 Adsorber

4IU10-050 Coalescer

4IU15-060 Coalescer

4IU15-095 Coalescer

6IU10-025 Coalescer

Our filtration equipment is used in a wide range of industries:

Advanced production process:

| Contact us | john Fimler Filter WeChat: +8613632692595 Whatsapp:+8613632692595 E-mail:4798742@qq.com |