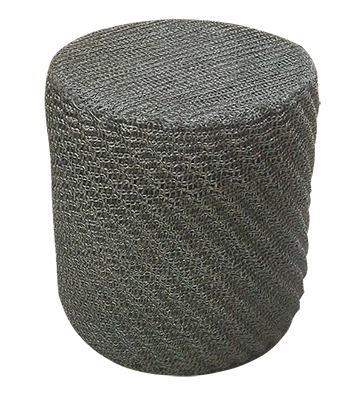

Candle Filter

Mist Eliminator

Offers a complete line of fiber bed mist eliminators and systems to abate liquid mist and aerosol emissions. Our fiber bed mist eliminators, also referred to as fiber bed filters or candle filters, are optimal for removing sub-micron liquid aerosols from gas and air streams. Filters designs and manufactures fibered coalescing filters for use in a wide range of industries and application facilities where abatement of stack emissions is critical to regulatory compliance.

Candle Filter Mist Eliminator remove corrosive mists from exhaust air streams when large entrained droplets are present. Many processes generate mists which do not require a scrubber for pollution control. In these applications, mist eliminators perform effectively at a much lower cost than conventional packed bed scrubbers. Mist elimination is a relatively old science. Small mist particles (tiny particles of liquid or dissolved solids suspended in a stream of gas) are an inevitable product of many manufacturing processes. Within a process, these particles can cause problems such as corrosion of equipment, contamination of product, fouling of heat exchangers and catalyst and damage to instruments, when released to the atmosphere, these mist particles can cause violations of air pollution emission standards or of capacity regulations.

Fiber Filters

Mist Eliminator Offer:

High Removal Efficiency Filter Performance

Long Filter Life

Increased Surface Area

Low Operating Costs

Low Maintenance Costs

Filter re-packing services.

Mist Eliminators are used to remove liquid droplets from a gas stream to:

Control stack emissions to the atmosphere

Eliminate or reduce damage of equipment caused by corrosive or fouling liquid droplets

Recover valuable liquids

Fiber Bed Mist Eliminators

Mist Eliminators remove corrosive mists from exhaust air streams when large entrained droplets are present. Many processes generate mists which do not require a scrubber for pollution control. In these applications, mist eliminators perform effectively at a much lower cost than conventional packed bed scrubbers. Mist elimination is a relatively old science. Small mist particles (tiny particles of liquid or dissolved solids suspended in a stream of gas) are an inevitable product of many manufacturing processes. Within a process, these particles can cause problems such as corrosion of equipment, contamination of product, fouling of heat exchangers and catalyst and damage to instruments, When released to the atmosphere, these mist particles can cause violations of air pollution emission standards or of capacity regulations.

Multi Knit Mesh

Column Packing

Multi Knit Mesh Column Packing is high performance porous knitted mesh packing for fractional distillation towers operating at reduced pressure or atmospheric pressure ideal for separation of heat sensitive material, high added products and close boiling fractions and for pressure drop. Multi Mesh has very low E. T. P. value, it gives higher throughout, high separation efficiency and lower energy consumption that random packing and Trays.

Typical Application

Flavors & Fragrances

Pharmaceuticals

Plasticizer esters

High MW ether alcohols

Fatty acids, amides, Alcohols

High B P Solvents.

Advantages

Reduce tower diameter and height.

Minimize inventory in column.

Increase product purity and output.

Increase mechanical strength and durability.

MULTI-MESH Column packing pads consists of fine strands of multifilament wires, knitted into a roll of required column diameter. The fine wires used for construction presents an m8/ m. The open structures are per unit volume typically 2000 spaces produced by the crimp provides tortuous passage ways for the rising vapour, which promote effective mixing by causing commodious division and reformulation on the vapour steams similarly the bunched wires, which are of capillary nature provide. The streams wherever the wire cross. In addition, the capillary action of the wire makes it an excellent distributor and readily removes liquid streams into the column and redistributions are not necessary.

Demister Pads

Mist Extractors ( Mesh Pad )

Demister Pads are porous blankets of wire or plastic knitted mesh, designed and constructed for efficient and economical removal of entrained liquid droplets from vapour streams. The pads can be fabricated in any desired size and shape. Normally demister pad is installed in such a way that vapour flow is upward. When vapour and entrained liquid droplets pass through a demister pad, the vapour passes easily but liquid droplets, due to their greater inertia, cannot make the necessary sharp turns and are thrown into contact with the wire surfaces and briefly held there. As more droplets enter the pad and collect on the wires, they grow in size, run down the wire to the bottom surface of the mesh separator and fall from the unit. Over head vapour is now free of entrained liquid.

Typical Process Application For Mist Eliminator

Demister pad prevent loss of valuable product and produces high quality condensate suitable for use a boiler’s feed water. The applications are in the Evaporator, Refining vacuum tower, Refining lube towers, Steam drums, Absorber, Scrubbers, Separators vessels and knock out drums. and any process vessels handling liquid and vapor where complete separation of entrained liquid droplets is desired from gas/vapor phase.

The allowable velocity depends on liquid density, surface tension, droplet size and quantity of entrainment. The pressure drop is negligible and the efficiency is high depending on vapour and liquid loading.

Salient features

High removal efficiency

Negligible pressure drop, less than 25mm of water gauge

No maintenance or service required

No corrosion or temperature limitations

Easily installed in existing vessels

No limitation on size or shape.

Our filtration equipment is used in a wide range of industries:

| Contact us | john Fimler Filter WeChat: +8613632692595 Whatsapp:+8613632692595 E-mail:4798742@qq.com |

【 Go Back 】 | 【 Close this window 】