Warm Tips:

We can supply most of the manufacturers of filter accessories, complete model, the goods quickly, quality assurance.

Limited space, not one by one show, if demand, please contact, thank you!

Air filtration, liquid filtration, gas filtration, hydraulic oil filtration, petroleum filtration,

dust filtration, coalescers, separators - we can all produce!

No matter which brand - we can produce!

No matter which model - we can produce!

You have needs - please contact us.

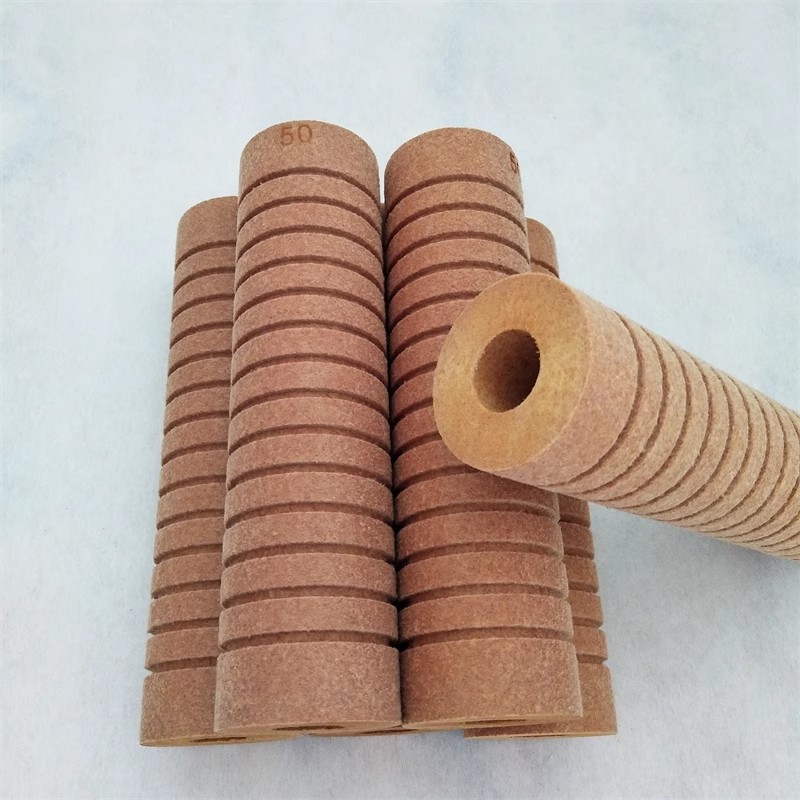

Phenolic Resin Bonded Filter Cartridge

General Information

Phenolic resin bonded filter cartridges, also known as phenolic resin fiber filter cartridges, are filter cartridges that use high-pressure resin fiber for processing and synthesis. The surface of the filter cartridge is formed with a layer of resin fiber filaments, and the internal compression structure is strong and durable.

TaRex series phenolic resin composite filter cartridge has a unique and patented two-layer structure filter design to ensure the maximum particle removal effect and the life of viscous fluid filtration, adapting to high-temperature, high-viscosity fluid filtration containing phenolic or resin raw materials.

Due to its high filtration efficiency and long-lasting life span, it has been unanimously recognized by customers. At present, TaRex resin bonded filter cartridges are widely used in ink filtration, water filtration, oil field oil filtration, petrochemical industry filtration, and high-viscosity liquid filtration, etc.

Due to its unique manufacturing process, it has the characteristics of rigidity, resin reinforcement and progressive structure, thus avoiding the disadvantages of bypass, leakage and penetration of other flexible and deformable filter cartridges (such as melt blown filter cartridges, string wound filter cartridges and spiral wound filter cartridges).

Features

· High quality raw material

· High thermal and chemical resistance

· Simple and economical cartridge replacement

· Expanded removal ratings

Benefits

· The external spiral structure increases the surface area while reducing the loose debris and pollution of machine-made products.

· The extremely long acrylic fiber increases the fiber length and can resist the damage and fiber movement of the phenolic resin filter cartridge.

· The injection of phenolic resin enhances the viscosity of the filter cartridge which can be used for fluids up to 15,000 SSU (3200 cks).

· Optimized structure ensures no medium pollution.

· Flow rate up to 5 gpm (about 2.3 m3/h) per 10 inch long filter cartridge.

Applications

· Paints

· Printing inks

· Adhesives

· Resins

· Emulsions

· Chemical coatings

· Organic solvents

· Petroleum products

· Process water

· Oilfield fluids

· Animal oils

· Waxes

· Plasticizers etc.

Specifications

Materials of Structure:

• Filtration Media: Acrylic Fiber + Phenolic Resin

Size:

• Outer Diameter: 65 mm, Inner Diameter: 28 mm

• Length: 9.75″, 10″, 19.5″, 20″, 29.25″, 30″, 39″, 40″

Removal Ratings:

• 1 μm, 2 μm, 3 μm, 5 μm, 10 μm, 20 μm, 50 μm, 75 μm, 100 μm, 125 μm, 150 μm, 200 μm, 250 μm

Operating Conditions

· Recommended change-out differential pressure: 2.4 bar (35 psi)

· Maximum differential pressure:

4.8 bar (70 psi) @ 20°C (68°F)

2.8 bar (40 psi) @ 65°C (150°F)

· Maximum operating temperature: 145°C (293°F)

PRO100-19 PRO200-20 PRO50-10

PRO100-29 PRO200-29 PRO50-19

PRO100-30 PRO200-30 PRO50-20

PRO100-39 PRO200-39 PRO50-20Z

PRO100-9 PRO200-40 PRO50-29

PRO10-10 PRO200-9 PRO50-29K

PRO10-10K PRO2-10 PRO50-3.75

PRO10-19 PRO2-10TC-E PRO50-30

PRO10-19K PRO2-10XA PRO50-30OB

PRO10-20 PRO2-19 PRO50-30TC-E

PRO10-29 PRO2-19K PRO50-30TC-N

PRO10-29.5NB PRO2-19NB PRO50-30XA

PRO10-29C PRO2-20 PRO50-30XB

PRO10-29NB PRO2-20CXC PRO50-39

PRO10-29TC-E PRO2-20K PRO50-39TF-V

PRO10-29TC-N PRO2-20QG PRO50-4

PRO10-29XB PRO2-20TC-E PRO50-4.875

PRO10-3.75 PRO2-29 PRO50-40

PRO10-30 PRO2-29.5 PRO50-40OB

PRO10-30XA PRO2-30 PRO50-5

PRO10-39 PRO2-30K PRO50-9

PRO10-39COB PRO2-30NB PRO50-9K

PRO10-39TC-N PRO2-30NTC-V PRO50-UNC

PRO10-39XB PRO2-30OB PRO5-10

PRO10-4 PRO2-30OB-N PRO5-19

PRO10-4.75 PRO2-30XA PRO5-20

PRO10-4.875 PRO2-39 PRO5-20XA

PRO10-40 PRO2-39C PRO5-29

PRO-1040 DOE PRO2-4.875 PRO5-29.5

PRO10-40TC-N PRO2-40 PRO5-29C

PRO10-40XA PRO250-10 PRO5-29TC-N

PRO10-40XB PRO250-19 PRO5-29XA

PRO10-9 PRO250-20 PRO5-30

PRO1-10 PRO250-29 PRO5-30C

PRO1-19 PRO250-30 PRO5-30NTC-N

PRO125-10 PRO250-39 PRO5-30OB

PRO125-19 PRO250-40 PRO5-30TC-N

PRO125-20 PRO250-9 PRO5-30XA

PRO125-20TC-V PRO25-10 PRO5-39

PRO125-20XA PRO25-19 PRO5-40

PRO125-29 PRO25-20 PRO5-40TC-E

PRO125-29NB PRO25-20OB PRO5-40TC-N

PRO125-29-PSI PRO25-20TC-E PRO5-40XA

PRO125-29XB PRO25-20Z PRO5-40XB

PRO125-30 PRO25-29 PRO5-7.75

PRO125-30C PRO25-29C PRO5-8

PRO125-30NB PRO25-3.75 PRO5-9

PRO125-30OB PRO25-30 PRO75-10

PRO125-30XA PRO25-30C PRO75-10K

PRO125-30XB PRO25-30C-TC-S PRO75-10TC-E

PRO125-39 PRO25-30CXC PRO75-19

PRO125-39TF-V PRO25-30OB PRO75-19K

PRO125-40 PRO25-30TC-N PRO75-20

PRO125-9 PRO25-30TC-V PRO75-20TC-E

PRO125-9K PRO25-30XA PRO75-20TC-V

PRO1-29 PRO25-30XB PRO75-29

PRO150-10 PRO25-34.5 PRO75-29K

PRO150-19 PRO25-39 PRO75-29XA

PRO150-20 PRO25-39NTC-N PRO75-3.75

PRO150-29 PRO25-39TC-E PRO75-30

PRO150-30 PRO25-39TC-N PRO75-30C

PRO150-30C PRO25-4 PRO75-30OB

PRO150-30OB PRO25-40 PRO75-30TC-E

PRO150-40 PRO25-40OB PRO75-30XA

PRO150-40OB PRO25-40TC-E PRO75-30XB

PRO150-9 PRO25-5 PRO75-39

PRO1-9 PRO25-9 PRO75-40

PRO200-10 PRO25-9K PRO75-9

PRO200-19 PRO2-9

Our filtration equipment is used in a wide range of industries:

Advanced production process:

| Contact us | john Fimler Filter WeChat: +8613632692595 Whatsapp:+8613632692595 E-mail:4798742@qq.com |

【 Go Back 】 | 【 Close this window 】